3D Printed Medical Gear Tailored To Babies

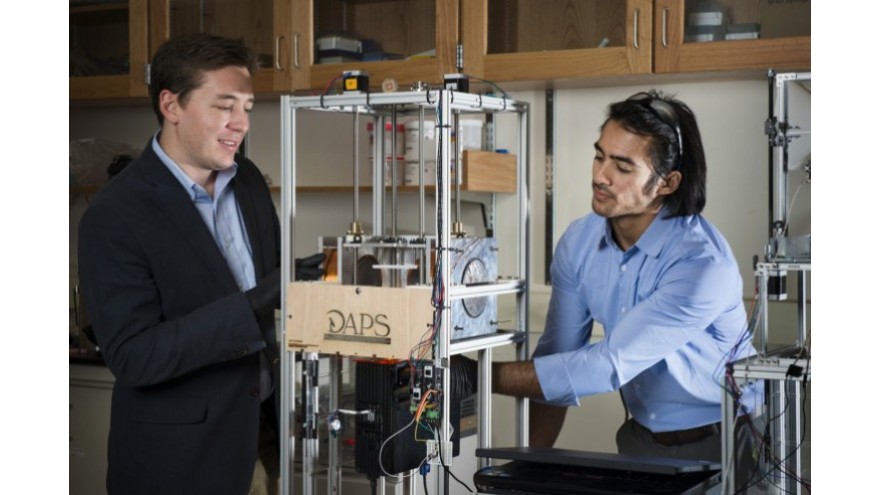

Researchers at Northeastern have begun creating custom plastic and ceramic implants that are customized to a particular patient. This means doctors can avoid injuring delicate tissues and prevent damage while inserting or implanting various devices.

Most medical hardware is stock – you go to the closet and pick out a catheter or implant and just stick it in. But what about situations where you need a teeny tiny connector for a premature baby or a specially-shaped brace? You turn to 3D printing.

“With neonatal care, each baby is a different size, each baby has a different set of problems,” said Randall Erb, assistant professor at Northeastern. “You can print a catheter whose geometry is specific to the individual patient, you can insert it up to a certain critical spot, you can avoid puncturing veins, and you can expedite delivery of the contents.”

The researchers described their technology in a recent paper.

The team uses stereolithography and magnetics to control the position of the ceramic fiber and place where it needs to flow. They magnetize the fibers first – a process approved by the FDA – and then they apply “ultralow magnetic fields to individual sections of the composite material—the ceramic fibers immersed in liquid plastic—to align the fibers according to the exacting specifications dictated by the product they are printing.” It’s a clever way to embed stronger materials into an object without actually extruding them.

The system uses both plastic and ceramic fibers to create rigid and

highly exact objects. The ceramic fiber is place in various

configurations in the object to make the holes and curves in the object

more durable. The researchers said this is the same system used by

“bones to tree” to create naturally strong objects.

The system is still in testing but expect the findings to find their way into your body sooner rather than later.

Comments